Project Description

Do You Have A Machining Project We Can Help With?

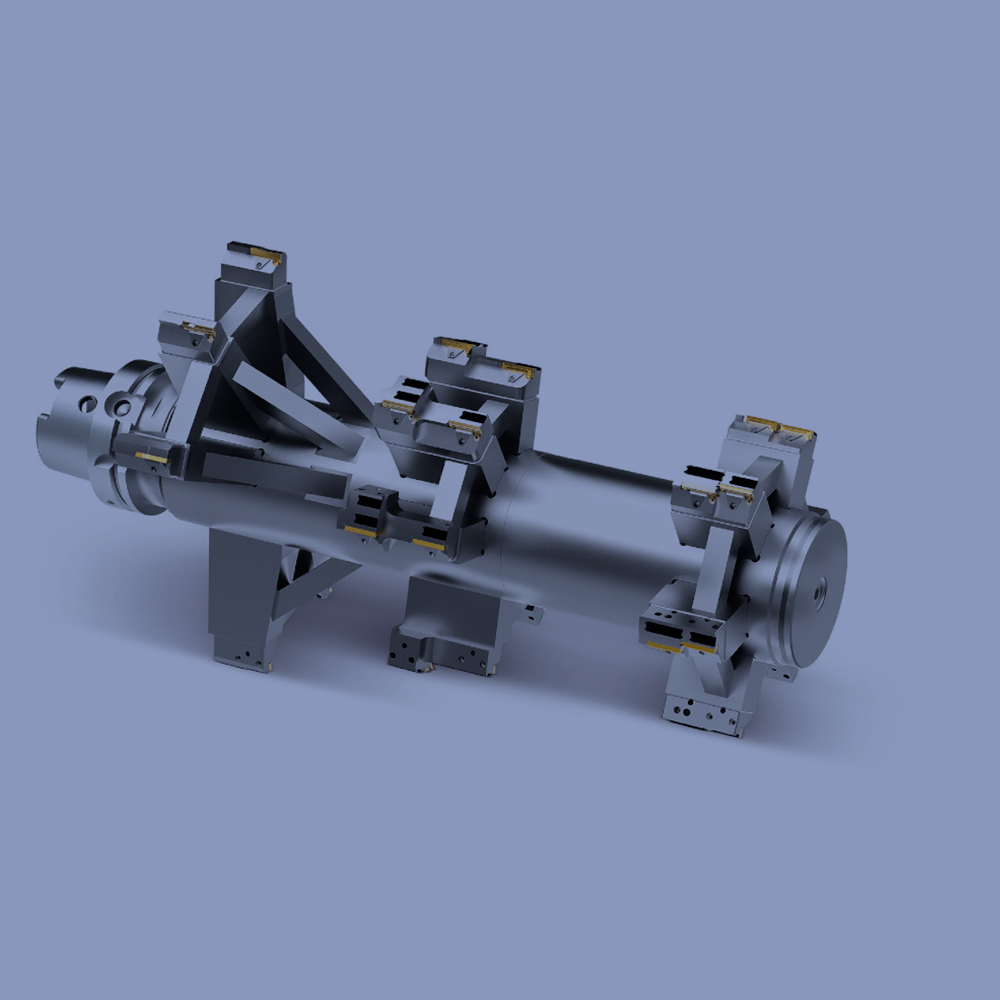

Machining Task

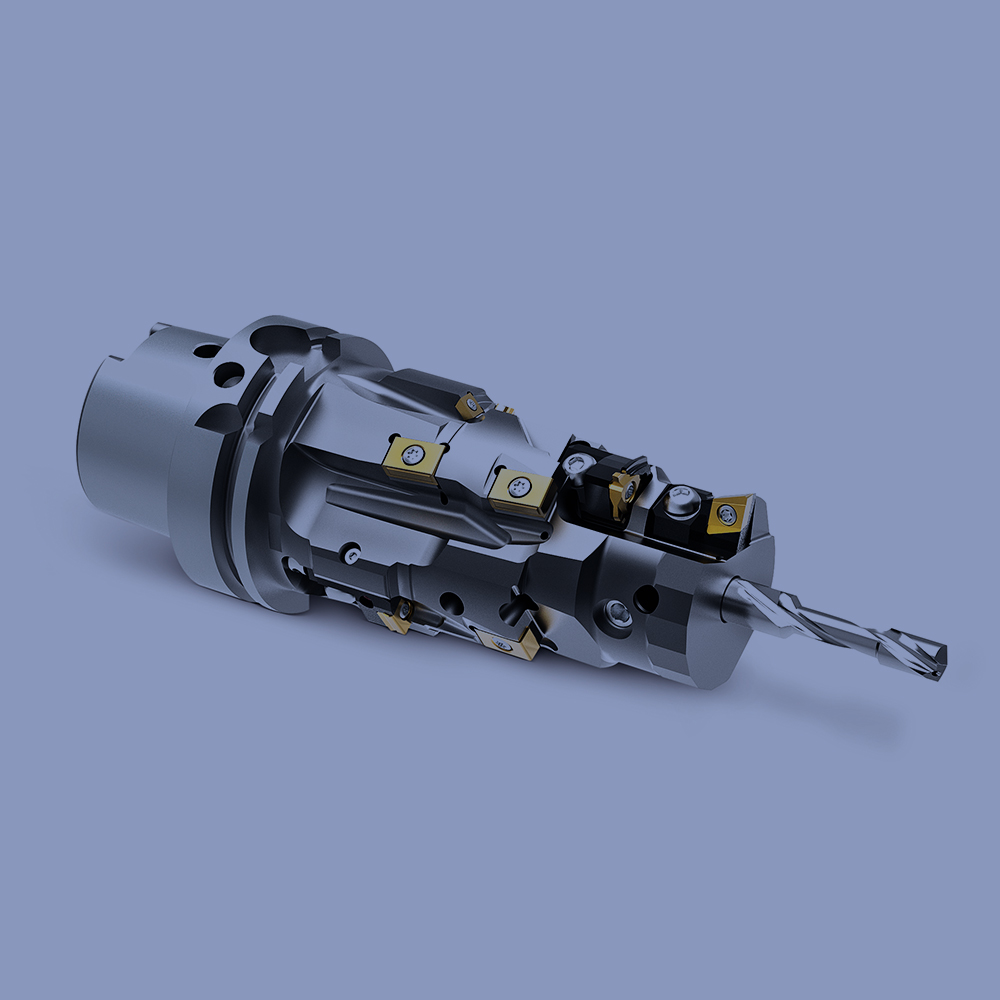

Machine downtimes in automated processes during mass production are a nightmare for the managerial staff. A possible reason for the occurrence of this situation is that the chips produced are not transported away quickly and reliably. However this aspect is important so that parts can be loaded reliably by robots without interruption. In this specific case, it is connecting rods that are manufactured. The connecting rods made of C70 steel are produced on highly automated systems in 20 shifts per week. Long chips regularly jam the automatic loading by the robots and prevent the correct clamping of the parts in multiple holders. The task was to optimise the chip formation in the existing process to machine the “small eye” with Ø 33N7 to ensure a stable process.

Challenge

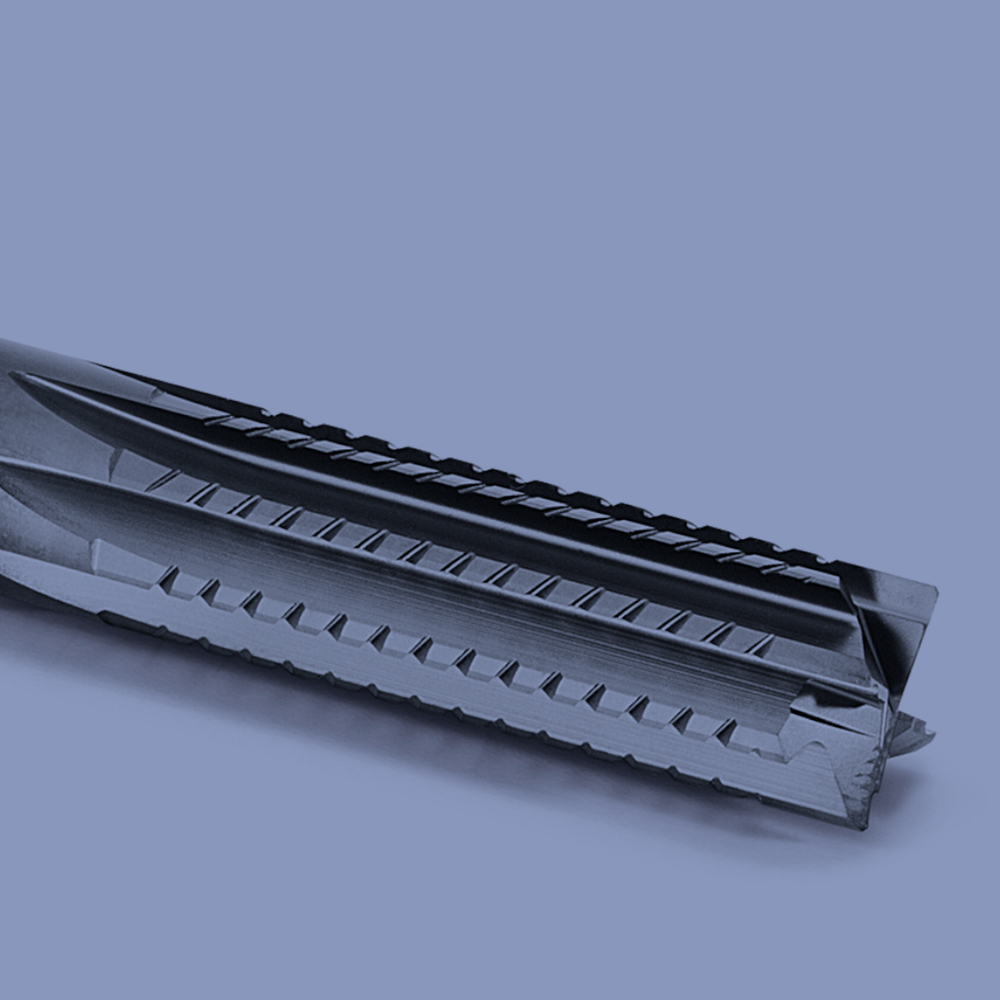

During the fine machining of steel materials such as C70, the challenge is to reliably break the very thin and therefore highly flexible chips into small chips that are easy to transport. This aspect is crucial for a continuous process. At the same time there must not be any shortfalls in the productivity and output. The high cutting speeds, feeds and the long tool lives of modern high performance tools must also be maintained.

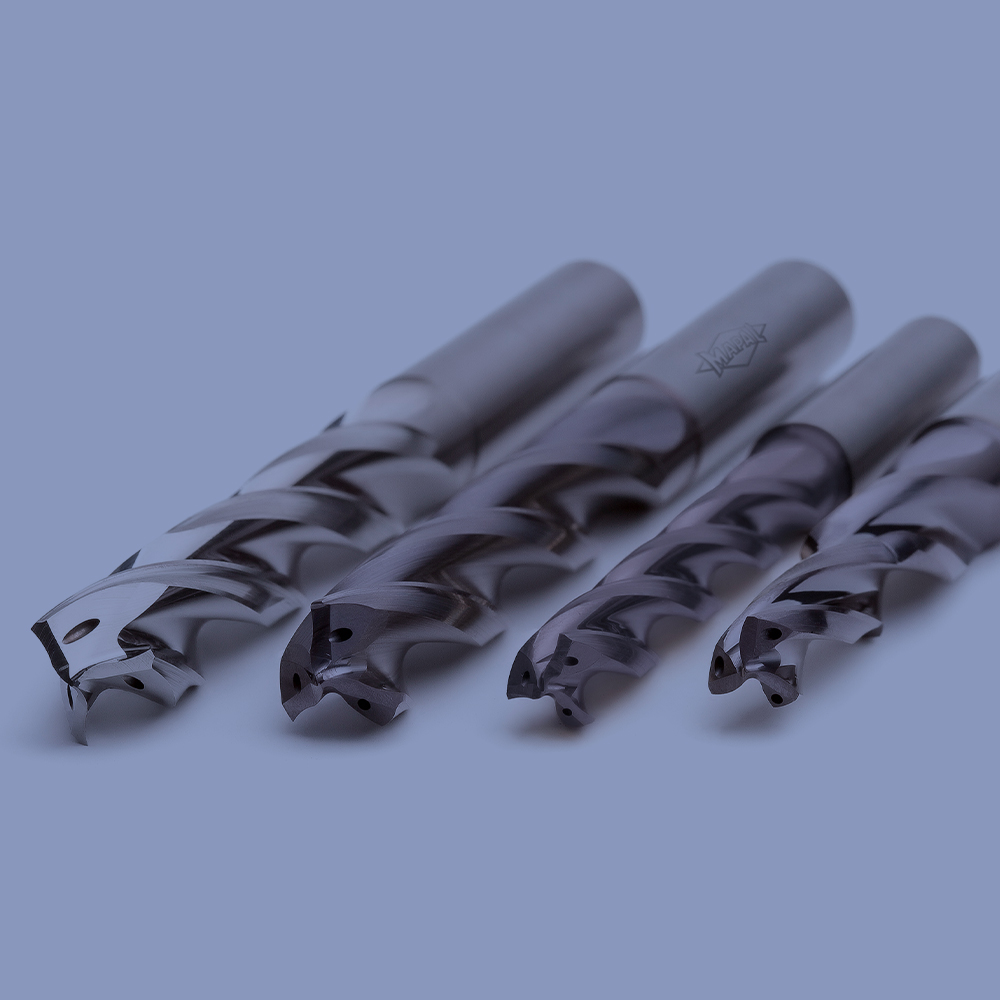

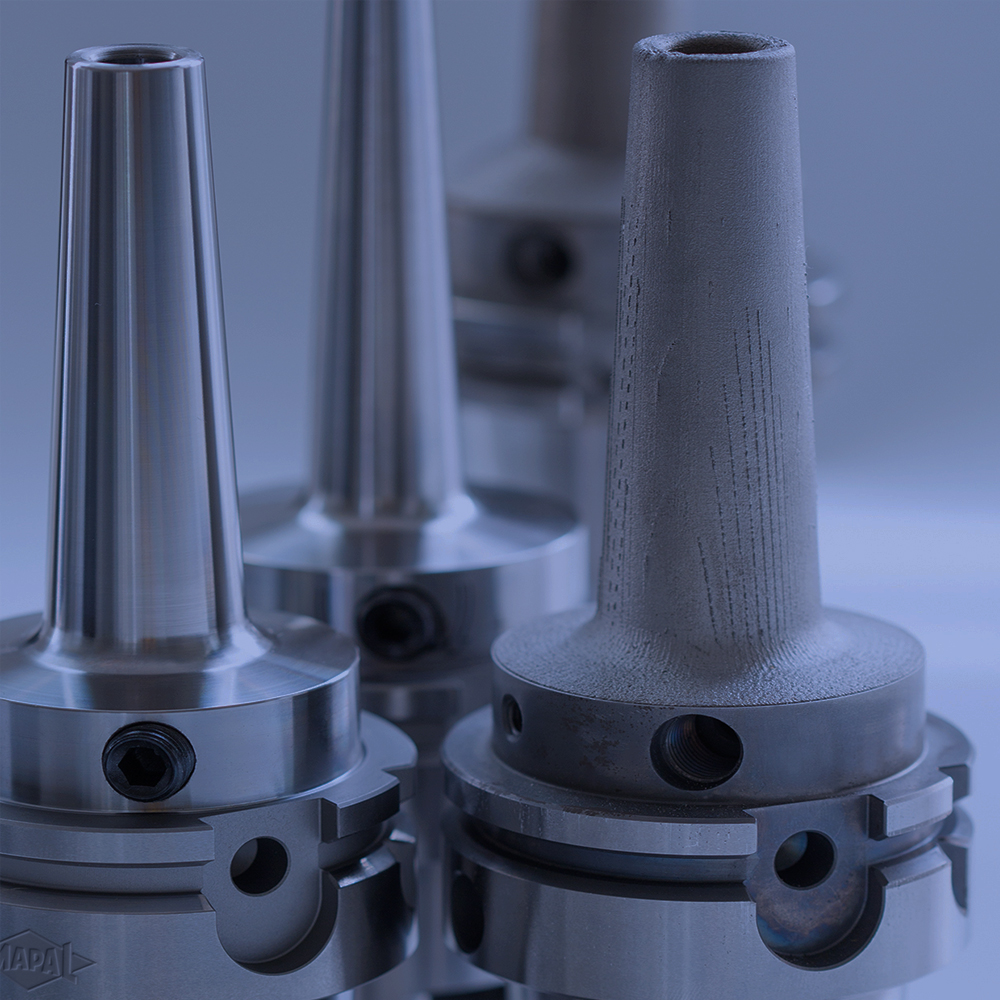

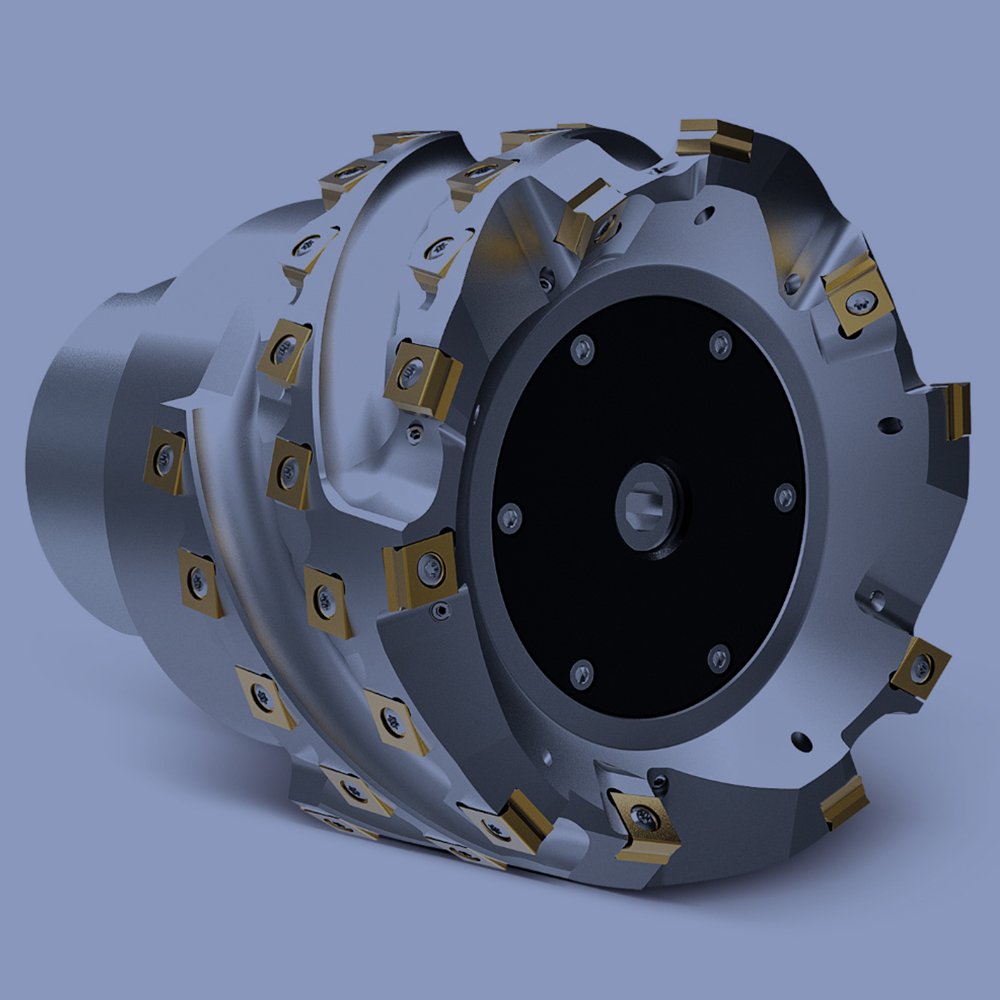

Our Solution

To address these requirements, MAPAL specialists have developed a modified design of an HPR reamer. Due to the specific design of the blade geometry, the chip is reliably broken. This action is provided by a special lead with chip breaker. The high cutting and feed rates of vc = 140 m/min and vf = 1500 mm/min are retained and short chips that are easy to transport away are produced. Through an additional optimisation of the cutting material, the tool life was increased to 10,000 parts.

MAPAL Effect

Due to this process optimisation with a MAPAL HPR tool, it was possible to eliminate the machine downtime. As a result, and due to the long tool life, the productivity was significantly increased. The process runs reliably and stably – the nightmare of downtimes is a thing of the past!

MAPAL Effect

Stable and reliable process

30% reduction in machine downtime

40% longer tool life

Lower machining costs

All customer needs reliably achieved

The MAPAL Effect

When something exceptional develops between us:

That’s the MAPAL Effect.