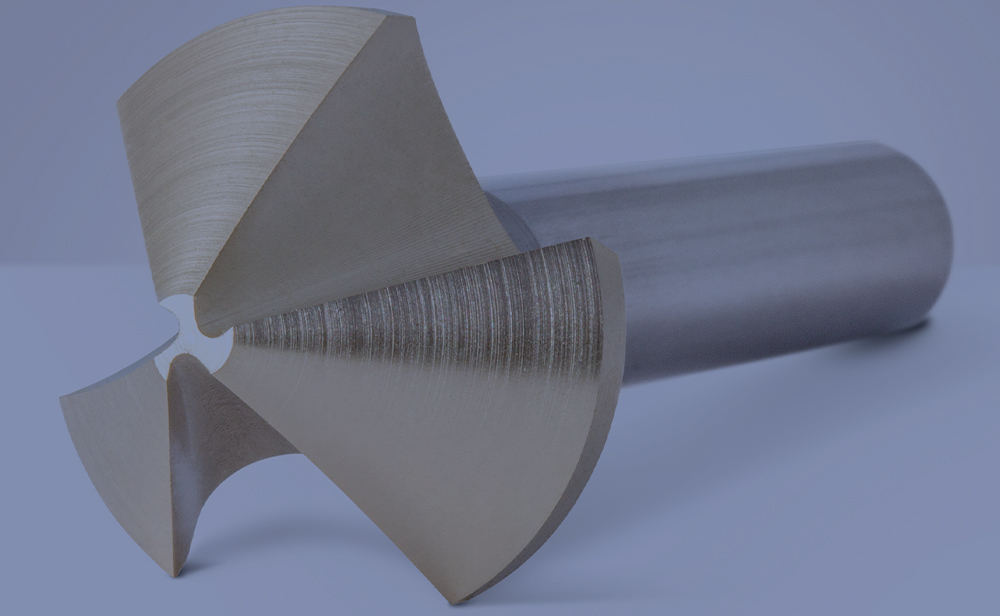

No bore without a countersink, that is a widely applicable rule. For this reason, MAPAL has a very successful product in its portfolio for the machining step. The production of the patented countersinks is being taken to a new level in 2022, both in terms of technology and processes, making a significant contribution to sustainable production.

The patented countersinks are designed with three cutting edges and have extreme unequal spacing. The design reduces the axial forces by 50 per cent as well as the forces acting perpendicular to the tool axis. This results in significantly less vibration on the tool during machining and consequently increased accuracy and better surface values. The contact of bolt and rivet hole connections is directly improved, and there is no setting under load. The smooth running of the tools also reduces the load on the machine. Users therefore run the MAPAL countersinks at higher cutting speeds and achieve long tool lives. Frank Dreher, Managing Director of the Centre of Competence for multi-bladed reamers at the MAPAL Group, explains: “Our countersinks prove themselves time and time again in use

– both the HSS variant and the solid carbide countersinks for machining demanding workpiece materials such as titanium, high-alloy cast iron, Inconel or CFRP.” This is why MAPAL is investing millions in the Winterlingen site in 2022 and particularly in countersink manufacturing. As a result, a completely new manufacturing technology is being introduced outside of machining: “This reduces our use of material and improves our energy balance.” MAPAL is also investing in the connectivity and automation of processes. For instance, through advanced image processing technology for pre-positioning in the machines, resulting in a reduction in non-productive time. Dreher points out: “We deliberately focus our production to the Winterlingen site, on manufacturing in Germany. Of course, we are encouraged by the feedback from our customers, who very much appreciate the price-performance ratio of our countersinks. Thanks to the investments in 2022, we ensure short delivery times and a reliably high level of quality.”

Dear readers,

and business associates,

We had hoped for a return to normality in 2022. The war in Ukraine and its unforeseeable effects, as well as the ongoing pandemic, however, do not allow for this. It is all the more important for us to focus on our business activities.

We took a big step at MAPAL in February by finalising our new range of catalogues for standard tools. The new catalogues include a completely reworked product portfolio with powerful tools for bore machining, milling and tool clamping. The products are largely available from stock and can be delivered quickly.

The high performance, quality and precision of MAPAL cutting tools can make your machining work even more cost effective. Our added value and quality promise: We have the entire process in focus. You receive perfectly harmonised components including inserts, tools and tool clamping from a single source and thus gain a considerable advantage in performance. The new range of catalogues is available in a navigable PDF format. We dispense with a proactive postal dispatch of the catalogues and are taking sustainability considerations into account. We are positive that we are on the right track with our new product range and will remain your innovative and reliable partner. I am particularly proud of the high quality of our apprenticeship programme. In this way, we guarantee that our products are produced by highly qualified experts.

Our training programme scored a big victory this year: Two of our mechatronic engineer apprentices won the German championships for “Robot Systems Integration”. They prevailed against highly qualified teams and earned a ticket to this year’s world championships is Shanghai. Quite an achievement for the young men: They asserted themselves in a competitive environment and now have the opportunity to take part in an international professional competition at a young age. This was made possible both by their extraordinary personal commitment and the great importance that is placed on apprenticeships at MAPAL in one of the most modern training centres in the region.

I hope that personal encounters and a direct exchange with you will soon be possible again without restrictions.

Have a good read!

Yours,

Dr. Jochen Kress